1000 Tunnels

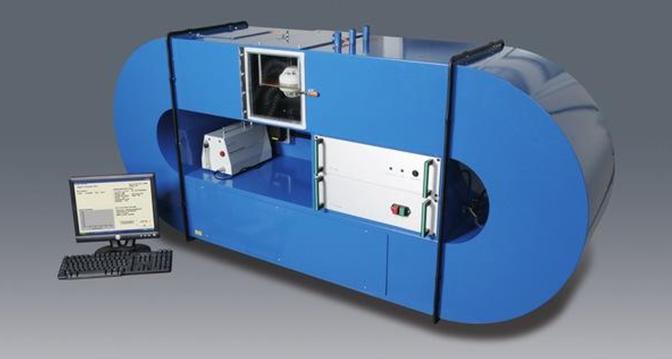

The 1000 Series Compact Fire Detector Test Tunnels are based on the same technology as the 2000 Series. They are, however, smaller, bench-top designs with control electronics integrated into the structure of the tunnel. The 1000 series test tunnels are ideally suited to performance testing to EN54-7 and EN54-5 for factory production control, but can also be used in test and R&D laboratories.

The PC base unit is pre-configured, and most of the wiring is already in place on the tunnel. Clear instructions (and our support where required) enable most users to start using their tunnel without one of our specialists having to be present.

• Smaller bench-top design

• Integrated control electronics

• Ideally suited for performance testing to EN54-7, EN54-29, EN14604 and EN54-5

• Comprehensive technical support

• Enables manufacturers to comply with AVCP requirements

• Optional training available

The following variants are available in the 1000 Series:

1300 heat detector test tunnel: This is designed for testing to EN54-5 with a starting temperature range from 250C to 550C. It is capable of carrying out testing for grades A1 to C to EN54-5 from the typical application temperature.

1400 combined smoke/heat detector test tunnel: This is designed for testing to EN54-7 and EN14604 from 250C to 550C, and to EN54-5 with a starting temperature range from 250C to 550C (as for 1300).

1700 heat detector test tunnel with cooling: This is designed for testing to EN54-5 with a starting temperature range from 50C to 550C. It is capable of carrying out testing for grades A1 to C to EN54-5 from the typical application temperature, and low temperature start tests for suffix R detectors.

1800 combined smoke/heat detector test tunnel with cooling: This is designed for testing to EN54-7 and EN14604 between 00C and 550C, and to EN54-5 with a starting temperature range from 50C to 550C (as for 1700).

The following additional options are available:

1000 Spare hatch with fixed mounting plate for up to 6 detectors (for 1100 test tunnel).

1001 Spare hatch with fixed mounting plate for up to 6 detectors (for 1300-1800 tunnels).

1002 Hatch with rotating detector mount for directional dependence testing, or for tests at a selected orientation (for 1100 test tunnel).

1003 Hatch with rotating detector mount for directional dependence testing, or for tests at a selected orientation (for 1300-1800 tunnels).

1004 Spare rotating detector mount (for use with 1002 or 1003).

1006 Airspeed meter (‘anemometer’) with analogue output integrated into the software.

1007 Interface and mount for MIC (standard reference for ionisation detectors).

1008 Optical scatter smoke sensor and software extension to enable simultaneous optical smoke and heat ramp testing (for use with 1400 and 1800).

1009 Dazzle test rig (non EN54-7 version for R&D application only).

1010 Hatch and motorised rotating detector mount with software control (for 1100 test tunnel).

1011 Hatch and motorised rotating detector mount with software control (for 1300-1800 tunnels).

The overall mechanical parameters are as follows.

Overall size of tunnel: 2.10m long * 0.70m wide * 0.93m high.

Internal cross section of duct (1100): 450mm wide by 290mm high.

Internal cross section of duct (1300-1800): 420mm wide by 260mm high.

Working volume cross section for smoke detectors: 360mm * 200mm.

Working volume cross section for heat detectors: 300mm * 75mm.

Extract via 150mm diameter flexible duct (requires a back draught shutter on exit).

2000 Series

2000 series laboratory fire detector test tunnels are full size, floor-standing pieces of laboratory equipment. They are mainly intended for type approval testing to EN14604, EN54-7 and EN54-5, but are also ideal for fire detector R&D. The duct size permits the capability (with optional accessories) to carry out the high airspeed (gusting) type test for ionisation smoke detectors, and the high luminance (dazzle) type test for optical smoke detectors.

• Capable of carrying out full range of tunnel tests to EN standards

• Ideal for test laboratories and fire detector R&D

• Ability to test to EN54-7, EN54-29, EN14604 and EN54-5

• Comprehensive technical support

• Additional training from AW Technology available

• Air flow deflector funnel available for high airspeed tests

• Full size dazzle rig available for testing optical detectors

The following variants are available in the 2000 series:

2200 Smoke Detector Test Tunnel:Designed for testing to EN54-7 and EN14604 over an operating temperature range from room temperature to 55°C.

2400 Combined Smoke / Heat Detector Test Tunnel:This is designed for testing to EN54-7 and EN14604 from room temperature to 55°C, and to EN54-5 with a starting temperature range from 25°C to 80°C. It is capable of carrying out testing for grades A1 to C to EN54-5, including tests from the maximum application temperature for grade C.

2700 Heat Detector Test Tunnel with Cooling:designed for testing to EN54-5 with a starting temperature range from 5°C to 55°C; capable of carrying out testing for grades A1 to C to EN54-5, including tests for suffix R detectors and tests from the maximum application temperature (80°C) for grade C.

2800 Combined Smoke / Heat Detector Test Tunnel with Cooling:Designed for testing to EN54-7 and EN14604 from 0°C to 55°C, and to EN54-5 with a starting temperature range from 5°C to 55°C (as 2700).

The following additional options are available for the 2000 series:

2001 Spare hatch with fixed mounting plate for up to 6 detectors

2003 Hatch with rotating detector mount for directional dependence testing, or for tests at a selected orientation

2004 Spare rotating detector mount (for use with hatch 2003)

2006 Airspeed meter (‘anemometer’) with analogue output integrated with the software

2007 Interface and mount for MIC (standard reference for ionisation detectors)

2008 Optical scatter smoke sensor and software extension to enable simultaneous optical smoke and heat ramp testing (for use with 2800).

2009 Dazzle test rig for high luminance type testing of optical smoke detectors

2010 Airflow deflector funnel for false alarm testing on ionisation detectors to EN54-7 at 5ms-1 and 10ms-1

2011 Hatch and motorised rotating detector mount with software control

The overall mechanical parameters are as follows.

Overall size of tunnel: 3.15m long * 0.86m wide * 1.60m high

Internal cross section of duct: 470mm wide by 370mm high

Working volume cross section for smoke detectors: 350mm * 250mm

Working volume cross section for heat detectors: 350mm * 100mm

Extract via 150mm diameter flexible duct (requires a back draught shutter)

Size of cooling unit supplied with 2700 and 2800: 0.9m long * 0.78m wide * 1.15m high.

3000 Series

The 3000 series optical detector calibration tunnels are designed for calibrating optical smoke detectors and smoke alarms in production. They are based on the 1000 series tunnels with an additional 1m long calibration section fitted. The tunnels can be maintained at a constant aerosol concentration for calibration, and are controlled by an optical scatter smoke sensor. The main section of the 3000 series tunnels is the same as the 1000 series, so can still be used for R&D and batch sensitivity testing as required.

• Integrated control electronics

• Ideally suited for calibration to EN54-7, EN54-29 and EN14604.

• Also used for calibration to UL standards.

• Can be used for QA testing to EN54-5

• Easy to assembly before use.

• Comprehensive technical support

• Enables manufacturers to comply with AVCP standards

• Optional training available

The following variants are available in the 3000 series:

3100 optical smoke detector calibration test tunnel:This is an extended version of the 1100 smoke only test tunnel, which includes a scatter sensor and calibration mounting plates (specified with order).

3400 Optical Smoke Detector Calibration Test Tunnel with Heat QA Test Capability:This is to the same design as the 3100 tunnel, but also includes heaters and thermal insulation to enable QA testing of heat detectors at up to 20Kmin-1 from 25oC.

3800 Optical Smoke Detector Calibration Test Tunnel with Heat QA Test Capability and cooling:This is to the same design as the 1900 tunnel, but also includes heaters and thermal insulation to enable QA testing of heat detectors at up to 20Kmin-1 from 25oC. Cooling is included to increase the rate of heat detector testing.

|